In the dynamic world of shipping, suppliers often perform near-miracles, delivering essential items at a moment’s notice—even during weekends and public holidays. These remarkable efforts are a lifeline for engineers and captains who find themselves needing critical supplies unexpectedly.

While ship suppliers excel at meeting urgent demands, frequently resorting to last-minute ordering has its risks. Despite their best efforts, the needed item might not be available immediately, potentially delaying the ship and incurring significant costs. Furthermore, urgent orders, often sourced from any available supplier, typically carry higher price tags due to expedited shipping and other logistics expenses.

For dedicated suppliers, the stress and frustration of fulfilling these urgent orders do not always justify the potentially higher profit margins. Failing to meet the expectations of a valued customer can be less than ideal, and the time spent sourcing unavailable items can outweigh the financial gain, especially for smaller orders.

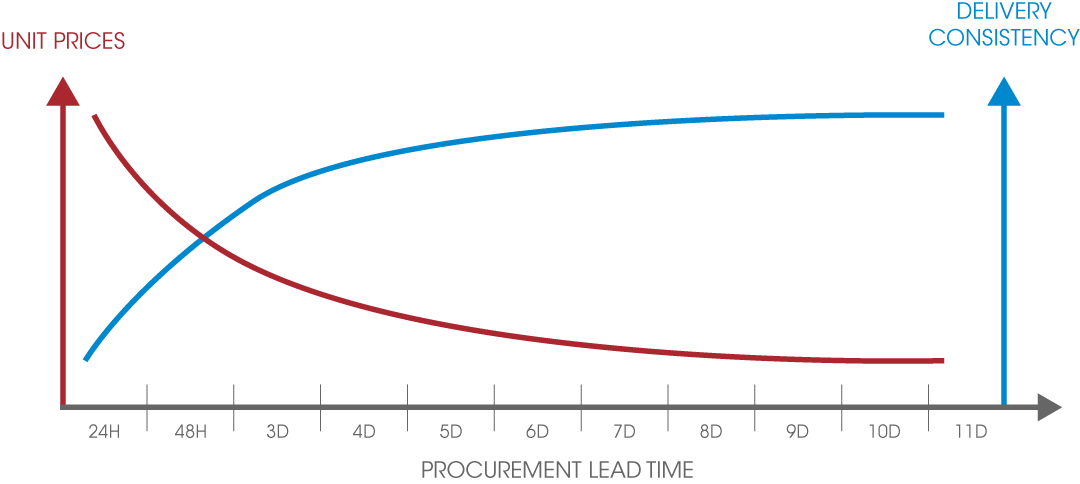

Fortunately, there is a promising alternative: well-planned procurement. Ships are complex, and while unexpected needs can arise, most requirements for stores, provisions, spare parts, and commodities are predictable. Strategic planning and early ordering not only reduce costs and ensure more reliable delivery but also alleviate stress for both the ship’s crew and suppliers. By planning ahead, companies can avoid the pitfalls of reactive purchasing, such as higher costs due to urgent demand, and can foster stronger relationships with suppliers, securing more favorable terms and pricing.

Research underscores the advantages of this approach, showing that early ordering results in lower prices, more consistent delivery, and improved service. Moreover, establishing a reliable inventory of standard, frequently used items, and aligning these with supplier catalogues ensures ships receive exactly what they need, maintaining quality and timeliness.

Effective maintenance systems help identify needs for spare parts and specific consumables, but broader planning is essential for non-maintenance items. Here, platforms like Moscord are transformative, offering a platform where buyers and suppliers can develop standardized shopping lists tailored to each port of delivery.

Moscord is continually expanding its supplier base, enhancing product accessibility in a structured, easily navigable format. By collaborating with leading shipping companies and managers to refine standard item lists, Moscord enables direct negotiations with suppliers, improving procurement efficiency.

By transitioning from spot purchasing to direct buying through early planning, both ships and their shore-based procurement teams benefit from better prices and reduced logistical burdens. Suppliers gain more time to source special or last-minute items, reducing pressure and increasing fulfillment rates. This proactive approach not only saves time and money but also fosters a more reliable and efficient procurement process, benefiting everyone involved.

By transitioning to proactive procurement, companies in the shipping industry and beyond can achieve greater control over their supply chains, resulting in reduced costs, improved operational efficiency, and a stronger competitive position in the market.